5 Best Rigid Insulation Panels for Camper Walls That Maximize Space

Discover the top 5 rigid insulation panels for camper walls that maximize thermal efficiency, save space, and resist moisture. Get expert tips for selecting the perfect insulation for your camping adventures.

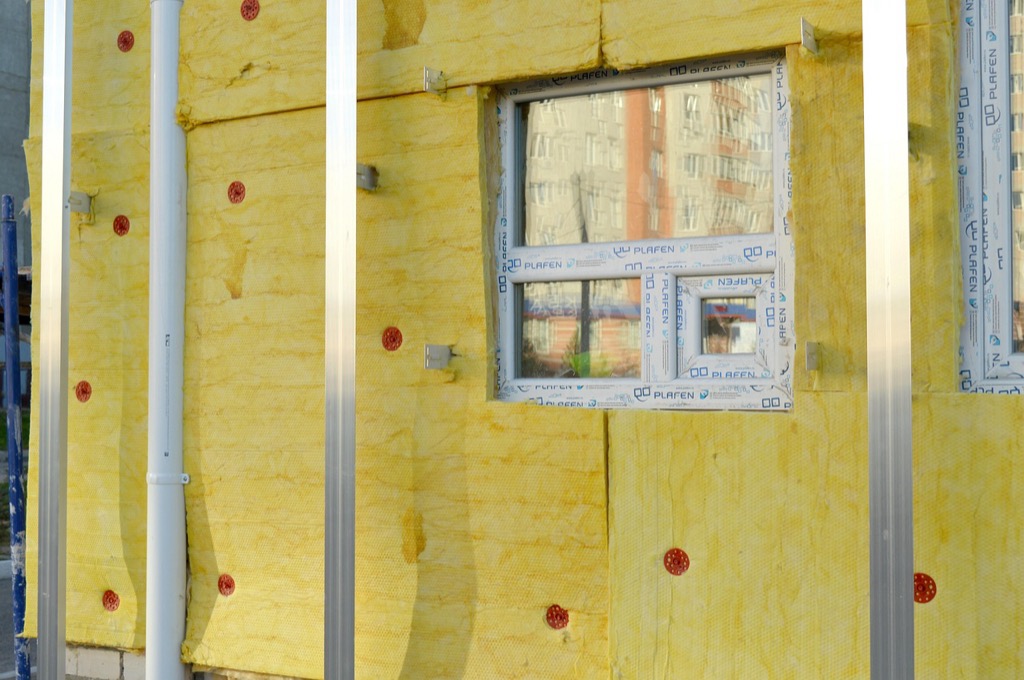

Looking to upgrade your camper’s insulation? Rigid insulation panels offer superior thermal protection while maximizing your limited space. They’re the smart choice for keeping your camper cozy in winter and cool in summer.

Choosing the right insulation can dramatically improve your camping experience and reduce energy costs. The market offers various options with different R-values, moisture resistance, and installation requirements. In this guide, you’ll discover the top five rigid insulation panels specifically suited for camper walls.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Introduction

Understanding Rigid Insulation for Your Camper: Priorities and Properties

R-Value Explained: Why It Matters in Small Spaces

R-value measures your insulation’s thermal resistance—the higher the number, the better it blocks heat transfer. In campers, every inch counts, making high R-value materials crucial. A panel with R-5 per inch delivers better insulation than R-3 alternatives in the same space, keeping your camper warmer in winter and cooler in summer while minimizing wall thickness.

Weight Considerations for Mobile Applications

Every pound matters in your camper, directly impacting fuel efficiency and towing capacity. Rigid foam panels like EPS weigh approximately 0.7-1 lb per cubic foot, while polyiso is even lighter at 0.5-0.7 lb. XPS falls between at roughly 1.3-2 lb. Always calculate total weight impact when insulating your entire camper, as lighter materials may justify slightly higher costs through fuel savings.

Moisture Resistance: Preventing Mold and Condensation Issues

Campers face constant moisture challenges from cooking, breathing, and weather changes. Closed-cell rigid insulations like XPS and polyiso naturally resist water absorption, with absorption rates below 0.3%. This water resistance prevents mold growth and maintains R-value performance over time. Always pair your insulation with proper ventilation to manage humidity and prevent condensation on walls during temperature fluctuations.

1. Polyisocyanurate (Polyiso) Panels: The High-Performance Option

Polyisocyanurate (Polyiso) panels stand out as a premier insulation choice for camper walls due to their exceptional thermal performance. With one of the highest R-values available in rigid insulation, these panels deliver superior temperature regulation while maximizing the limited space in your camper. They’re particularly effective in moderate climates, though their performance can decrease slightly in extremely cold temperatures below -20°C.

Top Polyiso Brands for Camper Applications

When selecting Polyiso panels for your camper project, focus on these industry-leading brands:

- Kingspan offers premium thermal performance with consistent quality and reliability

- Ecotherm provides eco-friendly options without sacrificing insulating properties

- Celotex specializes in thin-profile panels perfect for space-conscious camper conversions

Installation Tips for Maximum Effectiveness

- Ensure all surfaces are clean and completely dry before installation

- Secure panels using insulation stick pins or specialized adhesives designed for foam boards

- Apply a protective moisture barrier, as Polyiso is susceptible to water damage

- Consider layering Polyiso with other insulation types in extremely cold climates to maintain optimal R-value

- Create proper ventilation pathways to prevent condensation buildup behind panels

2. Extruded Polystyrene (XPS): The Versatile Middle-Ground

XPS insulation represents the perfect balance of performance, cost, and environmental impact for camper wall applications. With an R-value of approximately R-5 per inch of thickness, XPS boards offer strong thermal protection while providing excellent water resistance—a critical feature for mobile living spaces.

Color-Coded Strength Options Explained

XPS foam boards use a color-coding system that indicates density and durability. Blue and pink boards (from brands like Owens Corning and Foamular) offer higher density and superior strength, making them ideal for camper walls. White and green boards typically have lower density and cost less but provide reduced structural support and insulation performance.

Best XPS Thickness for Different Climate Zones

Climate conditions should dictate your XPS thickness selection. For warmer regions, 1-2 inches (R-5 to R-10) provides sufficient insulation for most campers. Moderate climate zones benefit from 2-3 inches (R-10 to R-15) of XPS. If you’re traveling through colder environments, invest in 3-4 inches (R-15 to R-20) to maintain interior comfort and prevent heat loss during freezing temperatures.

3. Expanded Polystyrene (EPS): The Budget-Friendly Solution

EPS foam boards offer an affordable insulation option for budget-conscious camper builders without sacrificing essential performance. This versatile material provides effective thermal protection while keeping your conversion costs manageable.

Density Ratings and Their Impact on Insulation Quality

EPS insulation comes in varying densities ranging from 1 to 3 pounds per cubic foot, directly affecting its performance. Higher density EPS (2-3 lb/ft³) provides improved thermal resistance at R-4 per inch and better structural integrity for camper walls. The density you choose impacts compression resistance, with denser panels maintaining their insulating properties longer even under the vibration and movement typical in mobile environments.

Working Around EPS Limitations in Campers

EPS’s primary limitation is its susceptibility to moisture damage, which requires strategic installation in camper applications. Combat this weakness by adding a proper vapor barrier between the insulation and your interior wall panels. For enhanced performance, consider a hybrid approach—combining EPS with other insulation types in moisture-prone areas or using foil-faced EPS boards that offer improved water resistance. These workarounds allow you to leverage EPS’s budget-friendly nature while minimizing its drawbacks.

4. Structural Insulated Panels (SIPs): The All-in-One Solution

Structural Insulated Panels offer a revolutionary approach to camper insulation by combining structural support and thermal protection in one product. These panels feature an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB), creating an integrated system that eliminates the need for separate framing and insulation components.

Space-Saving Benefits for Compact Builds

SIPs maximize your camper’s limited interior space by combining structural elements and insulation into a single panel. Unlike traditional methods that require separate framing and insulation layers, SIPs provide continuous insulation without thermal bridges. This space-efficient design can save up to 4 inches of wall thickness compared to conventional framing methods, giving you more usable living space inside your camper.

Custom Sizing Considerations for Camper Vans

SIPs can be precisely cut to fit your camper’s unique dimensions, eliminating awkward gaps that compromise thermal efficiency. Most manufacturers offer custom sizing options, allowing panels to be pre-cut for windows, doors, and utility access points. This precision fitting not only optimizes insulation performance but also reduces installation time by up to 60% compared to traditional framing and insulation methods.

5. Vacuum Insulated Panels (VIPs): The Premium Performance Choice

Vacuum Insulated Panels represent the cutting edge of camper insulation technology, delivering exceptional thermal performance in an ultra-thin profile that’s ideal for space-conscious builds.

Maximizing Thermal Efficiency in Ultra-Thin Spaces

VIPs achieve R-values up to R-30 per inch—nearly six times higher than standard rigid foam options. Their gas-tight enclosure surrounding a microporous core creates a vacuum that virtually eliminates heat transfer through conduction and convection. At just ¼-inch thickness, VIPs can deliver the same insulation performance as 2 inches of polyiso board, making them perfect for campers where every inch of interior space counts.

Cost-Benefit Analysis for High-End Builds

VIPs typically cost 5-8 times more than traditional rigid insulation, with prices ranging from $5-$8 per square foot. However, this premium can be justified in high-end builds where maximizing interior living space translates to enhanced comfort and functionality. The space savings also allows for thinner walls while maintaining superior thermal performance, potentially improving aerodynamics and fuel efficiency during travel. For four-season campers facing extreme temperature fluctuations, VIPs provide unmatched thermal stability.

Installation Best Practices for Rigid Insulation in Campers

Dealing with Curved Surfaces and Awkward Spaces

Cutting rigid insulation panels into smaller pieces allows them to conform to curved camper walls more effectively. Score XPS or EPS panels with a utility knife before bending them gently to follow contours without breaking. For extremely awkward spaces, use spray foam to fill gaps after installing the main panels, creating a seamless thermal envelope that prevents cold spots.

Sealing and Fastening Methods for Road Vibration

Apply construction adhesive in a continuous S-pattern to secure rigid panels to camper walls, preventing vibration-induced movement during travel. Supplement adhesive with mechanical fasteners every 12 inches, using plastic washers to prevent thermal bridging. Seal all panel seams with foil tape (for polyiso) or specialized insulation tape to create an unbroken thermal barrier that withstands constant road vibration without developing gaps.

Comparing Cost, Performance and Availability of Top Panel Options

Choosing the right rigid insulation for your camper walls doesn’t have to be overwhelming. Each panel type offers distinct advantages based on your priorities and budget. Polyiso delivers superior R-values for moderate climates while XPS provides excellent water resistance for all-season adventures.

Budget-conscious builders will appreciate EPS panels that balance cost and performance. If you’re looking for structural benefits alongside insulation SIPs offer an integrated solution that saves space and installation time.

For premium builds where maximum thermal efficiency in minimal space is paramount VIPs represent the ultimate innovation despite their higher cost. Remember to match your selection to your specific climate conditions usage patterns and available installation space.

Your perfectly insulated camper awaits with improved comfort reduced energy costs and protection against moisture issues regardless of which option you choose.

Frequently Asked Questions

What are rigid insulation panels for campers?

Rigid insulation panels are solid foam boards used to insulate camper walls. They provide excellent thermal protection in a compact form, helping to maintain comfortable interior temperatures while optimizing limited space. These panels come in various materials including Polyiso, XPS, EPS, SIPs, and VIPs, each with different thermal performance characteristics and moisture resistance properties.

Why is R-value important when choosing camper insulation?

R-value measures insulation’s thermal resistance—higher values mean better insulation. In campers where space is limited, high R-value materials maximize thermal efficiency without consuming excessive wall thickness. This helps maintain comfortable temperatures, reduces energy consumption for heating/cooling, and allows for more living space. Different climates require different minimum R-values for optimal performance.

Are some insulation panels better for moisture resistance?

Yes, closed-cell rigid insulations like XPS and Polyiso offer superior moisture resistance compared to EPS. XPS is particularly effective with its water-resistant structure, making it ideal for humid environments. EPS is more susceptible to moisture damage and requires vapor barriers. For maximum protection in high-humidity areas, pair moisture-resistant panels with proper ventilation and vapor barriers.

What is the best insulation for extremely cold climates?

For extreme cold, XPS insulation maintains consistent performance at low temperatures, while Vacuum Insulated Panels (VIPs) offer the highest R-value per inch (up to R-30). SIPs provide excellent continuous insulation with minimal thermal bridging. Consider using thicker panels (3-4 inches) or layering different insulation types. Polyiso, while excellent overall, may experience reduced effectiveness in extremely cold conditions.

How do you install rigid insulation on curved camper walls?

For curved surfaces, cut rigid panels into smaller, more flexible pieces that can conform to the curve. Score thicker panels partially through to increase flexibility. Use construction adhesive specifically designed for foam insulation to secure panels, and fill gaps with spray foam insulation. Complete the installation by sealing all seams with specialized insulation tape to create a continuous thermal barrier.

Are Vacuum Insulated Panels worth the higher cost?

VIPs can be worth their premium price (5-8 times more than traditional rigid insulation) in specific situations. Their ultra-high R-value (up to R-30 per inch) in an extremely thin profile maximizes interior living space while providing superior thermal performance. For high-end builds, four-season campers, and situations where space conservation is critical, the long-term benefits in comfort and energy savings can justify the investment.

What thickness of insulation should I use for my camper?

The ideal thickness depends on your climate and available space. For warmer regions, 1-2 inches is generally sufficient. Moderate climates benefit from 2-3 inches, while cold environments require 3-4 inches for adequate thermal protection. Consider that thicker insulation reduces interior space but improves energy efficiency. For optimal results, prioritize high R-value materials in areas with space constraints.

How important is proper sealing when installing rigid insulation?

Proper sealing is critical for insulation effectiveness. Even small gaps can create significant heat loss and allow moisture infiltration, potentially leading to condensation and mold issues. Use specialized insulation tape to seal all panel joints, spray foam to fill irregular spaces, and ensure complete contact between panels and camper walls. A continuous thermal envelope maximizes energy efficiency and prevents moisture-related problems.