5 Best Plumbing Pipe Insulation Products for Energy Efficiency That Slash Bills

Discover the top 5 pipe insulation products that can reduce energy bills by 3-4%, prevent frozen pipes, and pay for themselves within months. Compare foam, fiberglass, and tape options for your home.

Proper pipe insulation can slash your utility bills by up to 3-4% annually while preventing costly freeze damage during winter months. Uninsulated hot water pipes waste precious energy as heat escapes into surrounding air, while cold water pipes without protection risk freezing and potentially bursting when temperatures plummet.

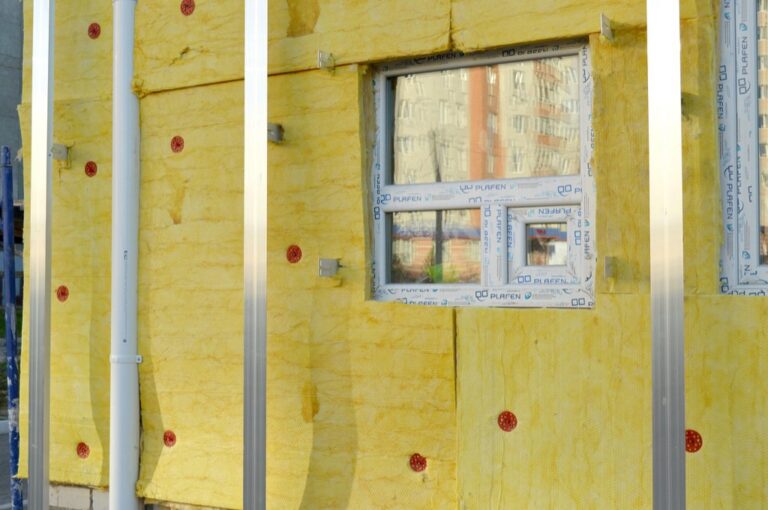

The right pipe insulation product creates a thermal barrier that maintains water temperature, reduces condensation, and extends the lifespan of your plumbing system. You’ll find numerous options on the market today, from foam tubes to fiberglass wraps, each offering different R-values, installation methods, and price points.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Insulating Your Plumbing Pipes Is Essential for Energy Efficiency

Understanding Heat Loss in Plumbing Systems

Uninsulated plumbing pipes constantly transfer heat to their surroundings, wasting significant energy. Hot water pipes can lose 2-4°F while traveling just 100 feet through uninsulated areas like basements or crawlspaces. This heat transfer occurs through conduction, convection, and radiation, with metal pipes being particularly susceptible due to their high thermal conductivity. During winter months, this heat loss accelerates dramatically when temperature differentials between pipe contents and ambient air increase.

The Financial Benefits of Proper Pipe Insulation

Insulating your plumbing pipes delivers impressive financial returns, often paying for itself within 6-12 months. The Department of Energy estimates homeowners can save 3-4% annually on utility bills through proper pipe insulation, translating to $30-$50 annually for the average household. Beyond energy savings, insulation prevents costly pipe bursts ($1,000-$4,000 in repairs) and extends system lifespan, reducing maintenance frequency and replacement expenses. These combined savings make pipe insulation one of the most cost-effective home efficiency upgrades available.

Armacell AP Armaflex: The Professional’s Choice for Pipe Insulation

Key Features and Benefits of AP Armaflex

Armacell AP Armaflex features an elastomeric foam construction with exceptional thermal conductivity (0.025 W/m·K) that significantly reduces heat loss. Its closed-cell structure prevents moisture transmission, eliminating condensation risks even in humid environments. Operating in temperatures from -50°C to +110°C, this CFC/HCFC-free insulation includes Microban antimicrobial protection. You’ll appreciate its sound-dampening properties, fire resistance ratings, and easy installation options through flexible tubes or self-sealing tapes.

Best Applications for Armacell Insulation Products

You’ll find AP Armaflex excels in both residential and commercial applications. It’s ideal for hot and cold water pipes, central heating systems, and air conditioning ducts due to its versatile temperature range. The moisture-resistant properties make it perfect for outdoor pipes and humid areas like bathrooms or basements. Its fire-resistant classification makes it suitable for spaces with higher fire risks including attics and utility rooms. Professional plumbers consistently choose Armaflex for its long-lasting performance and superior energy efficiency.

Frost King Pipe Insulation: Budget-Friendly Protection for Hot and Cold Pipes

Frost King stands out in the pipe insulation market as an accessible, cost-effective solution for homeowners looking to improve energy efficiency without breaking the bank.

Frost King’s Versatile Insulation Options

Frost King offers a range of pipe insulation products, including self-sealing polyethylene foam tubes and fiberglass wraps. Their foam tubes feature pre-slit designs with adhesive strips for tool-free installation, while their tubular sleeves come in various diameters to fit standard household pipes. These products typically provide R-values between 2 and 3, sufficient for most residential applications while remaining budget-friendly.

Installation Tips for Maximum Energy Savings

For optimal Frost King insulation performance, measure your pipes accurately before purchasing to ensure proper coverage. Apply insulation to both hot and cold water pipes, focusing first on unheated areas like basements, attics, and crawl spaces. Secure all seams with the built-in adhesive or foil tape to create a continuous thermal barrier. For exterior pipes, consider doubling up the insulation thickness during extreme cold conditions to prevent freezing and maximize energy conservation.

M-D Building Products Foam Pipe Insulation: Superior Protection Against Freezing

Temperature Range and Effectiveness

M-D Building Products Foam Pipe Insulation excels in residential plumbing applications where temperatures remain below 200°F (93°C). This insulation performs exceptionally well for cold water pipes, making it ideal for freeze protection in vulnerable areas like basements, crawl spaces, and exterior walls. Its effectiveness in maintaining water temperature translates directly to improved energy efficiency for both hot and cold water systems throughout your home.

Self-Sealing Technology Advantages

The self-sealing adhesive technology built into M-D Building Products insulation creates a significant advantage for homeowners. Installation requires no additional tools or adhesives—simply snap the pre-slit foam around your pipes and press the adhesive seam closed for an instant moisture-tight barrier. This user-friendly design makes it perfect for DIY projects, eliminating the frustration of tape or clamps while ensuring consistent protection against condensation and heat loss.

Owens Corning Fiberglass Pipe Insulation: Premium Thermal Performance

Owens Corning fiberglass pipe insulation stands as a premium solution for maximizing energy efficiency in plumbing systems. This professional-grade insulation utilizes woven glass strands to create exceptional thermal resistance, particularly excelling in high-temperature environments up to 1000°F (537°C).

The insulation’s superior R-value makes it especially effective for hot water systems with copper pipes. While it comes at a higher price point than alternatives, its excellent heat retention and fire-resistant properties make it a top choice for energy-conscious homeowners and professionals alike. The pre-formed tubes and wraps offer straightforward installation options, though protective equipment is recommended due to potential skin and respiratory irritation during handling.

Fiberglass vs. Foam Insulation Comparison

Fiberglass insulation delivers superior thermal performance with its higher R-value and ability to withstand extreme temperatures. Unlike foam products, fiberglass remains stable and effective even in systems reaching 1000°F, making it ideal for high-temperature applications where foam would deteriorate. While foam offers greater flexibility and easier DIY installation with its self-sealing adhesive, fiberglass provides more comprehensive thermal protection and fire resistance for critical plumbing areas experiencing significant heat flow.

Long-Term Durability and Energy Benefits

Owens Corning fiberglass maintains its insulating properties for decades with minimal degradation, outlasting most foam alternatives in challenging environments. This longevity translates to reduced replacement costs and consistent energy savings. The material’s superior thermal resistance can reduce heat loss by up to 90% in hot water systems, potentially saving homeowners $30-$50 annually on utility bills. Additionally, properly insulated pipes deliver hot water more efficiently, allowing for lower water heater temperature settings while maintaining performance and extending system lifespan.

Pipe Wrap Insulation Tape: Flexible Solution for Irregular Plumbing Configurations

Pipe wrap insulation tape offers exceptional versatility for plumbing systems with irregular configurations where standard tubular insulation fails to fit properly. This flexible solution conforms easily to odd angles, curves, and tight spaces while providing effective thermal protection against energy loss.

Best Practices for Applying Insulation Tape

Start with thoroughly cleaned and dried pipe surfaces to ensure proper adhesion. Measure your pipe diameter accurately before selecting the appropriate tape width. Always overlap each wrap by at least 50% for maximum thermal protection, creating a continuous seal without gaps. Secure the tape’s end with additional adhesive or a small piece of foil tape to prevent unwinding over time.

Combining Tape with Other Insulation Products

Layer insulation tape over foam or fiberglass sleeves to seal gaps at joints and fittings for comprehensive coverage. Use tape as a vapor barrier over porous insulation materials to prevent moisture infiltration and condensation. For outdoor applications, combine closed-cell foam insulation with weatherproof tape to create a complete thermal envelope resistant to environmental exposure. This multi-material approach maximizes energy efficiency in complex plumbing systems.

How to Choose the Right Pipe Insulation for Your Specific Needs

Factors to Consider When Selecting Plumbing Pipe Insulation

Selecting the right pipe insulation requires evaluating several key factors for maximum energy efficiency. Temperature requirements should guide your material choice—fiberglass and mineral wool excel for high-temperature applications (above 200°F), while foam works best for standard cold water pipes. Consider your pipe location carefully; exposed areas in basements or attics need higher R-values than interior walls. The pipe material matters too; copper pipes transfer heat differently than PVC. Finally, assess your specific goals: freezing prevention requires different insulation thickness than energy conservation.

Measuring Your Pipes for Proper Insulation Fit

Accurate measurements are crucial for effective pipe insulation installation. First, measure your pipe’s outer diameter using a flexible tape measure wrapped completely around the pipe, then divide by 3.14 (pi) to get the true diameter. Next, measure the total linear footage of all pipes requiring insulation, adding 10% extra for waste and mistakes. When purchasing insulation, match both the inner diameter of the insulation to your pipe’s outer diameter and the insulation thickness to your climate zone requirements. For pipes near exterior walls in cold climates, consider doubling the standard insulation thickness for superior protection.

Conclusion: Maximizing Energy Efficiency with the Right Pipe Insulation Investment

Investing in quality pipe insulation is one of the smartest decisions you’ll make for your home’s energy efficiency. Whether you choose Armacell’s professional-grade foam Frost King’s budget-friendly options or Owens Corning’s premium fiberglass you’re taking a significant step toward reducing utility bills and protecting your plumbing system.

Remember that the right insulation depends on your specific needs. Consider your climate pipe location and temperature requirements when making your selection. With proper installation you’ll enjoy warmer showers reduced condensation and protection against freezing while saving $30-$50 annually on energy costs.

The initial investment typically pays for itself within 6-12 months making pipe insulation a high-return home improvement that continues delivering benefits for years to come.

Frequently Asked Questions

How much can pipe insulation reduce my utility bills?

Proper pipe insulation can reduce your utility bills by 3-4% annually. This translates to approximately $30-$50 in savings per year for the average homeowner. The investment typically pays for itself within 6-12 months, making pipe insulation one of the most cost-effective home efficiency upgrades available.

Why do I need to insulate both hot and cold water pipes?

Hot water pipes lose heat energy when uninsulated, wasting money and reducing efficiency. Cold water pipes are at risk of freezing and bursting during winter months, which can cause expensive water damage. Insulating both types creates a thermal barrier, maintains water temperature, reduces condensation, and extends your plumbing system’s lifespan.

What is the best pipe insulation for high temperatures?

Owens Corning Fiberglass Pipe Insulation is ideal for high-temperature applications. It can withstand temperatures up to 1000°F (537°C), making it perfect for hot water systems with copper pipes. While more expensive than alternatives, its superior R-value, excellent heat retention, and fire-resistant properties make it the preferred choice for energy-conscious homeowners.

How do I measure pipes for proper insulation?

Measure pipe diameter by wrapping a string around the pipe and measuring the length, then dividing by 3.14 (π). For linear footage, measure the total length of exposed pipe requiring insulation. In cold climates, consider doubling insulation thickness for pipes near exterior walls for better protection and energy efficiency.

What is Armacell AP Armaflex and why is it recommended?

Armacell AP Armaflex is professional-grade elastomeric foam insulation with exceptional thermal conductivity (0.025 W/m·K). Its closed-cell structure prevents moisture transmission, eliminating condensation even in humid environments. It works in temperatures from -50°C to +110°C, contains antimicrobial protection, provides sound dampening, and offers fire resistance, making it popular among professional plumbers.

Are there budget-friendly pipe insulation options?

Frost King Pipe Insulation offers affordable options including self-sealing polyethylene foam tubes and fiberglass wraps. These products have R-values between 2 and 3, sufficient for most residential applications. M-D Building Products Foam Pipe Insulation is another economical choice with self-sealing adhesive technology that simplifies DIY installation.

How much heat do uninsulated pipes lose?

Uninsulated pipes can lose 2-4°F over just 100 feet, particularly in uninsulated areas like basements. This heat loss increases significantly in winter due to greater temperature differentials between the water and surrounding air. Continuous heat loss forces your water heater to work harder, increasing energy consumption and utility costs.

What insulation works best for irregular pipe configurations?

Pipe wrap insulation tape is ideal for irregular plumbing configurations where standard tubular insulation won’t fit properly. For maximum effectiveness, ensure surfaces are clean before application, measure pipe diameter accurately, and overlap wraps by at least 1/2 inch. Consider combining tape with other insulation products to seal gaps for comprehensive thermal protection.

How long does pipe insulation last?

Quality pipe insulation like Owens Corning fiberglass can maintain its insulating properties for decades with proper installation. Foam insulations typically have a lifespan of 5-10 years before they may begin to deteriorate. Proper installation and keeping insulation dry significantly extends its effective life and maximizes energy savings.

Can pipe insulation prevent frozen pipes?

Yes, proper pipe insulation significantly reduces the risk of frozen pipes. For maximum freeze protection in extreme cold, double the insulation thickness on exterior pipes or pipes in unheated spaces. While insulation alone may not prevent freezing in severe conditions, it dramatically slows heat loss, giving you valuable time during cold snaps.